Bluerock

Industrial buildings are critical in the nation’s storage and distribution of goods. There are approximately 19 billion square feet of industrial space of all types in the United States. (Costar) Subtypes include bulk distribution, light industrial (including “last-mile” facilities), truck terminals, flex, cold storage, outdoor storage and manufacturing. We explore the unique characteristics of these structures including physical attributes, demand drivers, locations, and tenancy types. Some industrial properties are referred to as logistics properties and we group the subsectors into the logistics and non-logistics category.

Logistics Category

Bulk Distribution

Bulk Distribution buildings are very large (250,000 – 1 million square feet+), single story structures, 36 feet+ clear height (floor to sprinkler), several dock loading doors, large truck turning radii, and very low office buildout. These facilities are used primarily for storage of goods and in many cases, located in urban perimeters, near highways to facilitate access and distribution of goods to smaller distribution centers. Tenants tend to be single users, large, brand name companies such as Amazon, Costco, and third-party logistics companies (3PLs) such as UPS and FedEx. Because of modern logistics practices and technologies, newer more modern facilities have unique leasing and demand advantages including higher ceiling heights and greater column spacing. Large transaction sizes and ease of capital deployment attracts significant institutional capital.

Source: CBRE

Light Industrial

Light Industrial (including “last mile”): buildings are smaller, typically less than 250,000 square feet, lower clear heights, and located in more “infill” locations. The smaller buildings tend to be more divisible and many times, multi-tenant facilities. Many light industrial buildings are also referred to as “small bay” or “small box” distinguished from big box warehousing. The smaller tenants/spaces also tend to have shorter leases leading to much shorter weighted average lease terms (WALT) compared to bulk distribution facilities. Tenant and lease diversification also distinguish small bay light industrial. Recent demand is being driven by 1) e-commerce and the desire for faster delivery times to end consumers, 2) new technology companies whose multi-purpose operations that include manufacturing, assembly, and storage, and 3) smaller manufacturing including 3D printing operations that require far less space. Infill locations are difficult to replicate, thus product tends to be older with very little new supply. Land values are considerably higher than most industrial buildings due to accessible infill locations. Smaller transaction sizes and more tedious diligence make this a more fragmented investment market.

Source: PERE

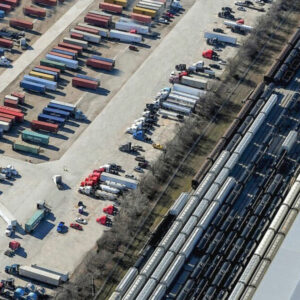

Truck Terminals

These facilities serve as “high-throughput” transshipment facilities for unloading products from an incoming vehicle and reloading quickly onto an outbound vehicle with no storage time in between. The term “flow through” means they are not designed or utilized for “long-term” warehousing. Truck terminals can serve as a point of transfer to consolidate loads or pallets traveling on a dedicated lane or in the same direction, or as a deconsolidation operation to break down truckloads and sort individual orders to the end user. Centralized truck terminals can help reduce inventory carrying costs by speeding up operations because they avoid put-away and retrieval of faster moving inventory. Truck terminals have very low floor to area (FAR) ratios as they comprise mostly land area with a smaller, long, narrow building. The concrete yards are used to secure park truck fleets or trailers. Much of the market is historically owner-occupied since the function is so closely tied to user operations, however investor interest has increased and new institutional funds have emerged specializing in this subtype.

Source: JLL

Cold Storage

Since these facilities are designed for perishable food storage and medicines, buildings are essentially refrigerated warehouses with very specialized interiors such as climate controlled docks, multiple temperature zones, blast freezers, copacking and repacking areas, bulk and rack storage, food processing and datestamping areas. Locations are many times near ports, rail facilities, or production facilities. It is estimated that cold storage facilities represent only about 2% of the total national industrial inventory. While some are purpose built, “box-in-a-box” options allow cold storage operations inside a standard warehouse. 3PLs operate in cold storage as well including DHL, Amazon, XPO Logistics, and Fedex.

Sources: Americold, AEW

Non-Logistics Category

Flex

Flexible buildings look like smaller industrial building structures from the exterior (low-rise, concrete tilt-ups), but interior uses include open office space, small storage, and possibly lab, manufacturing, or other specialized spaces. They typically have some, but not many overhead and loading doors, and ceiling heights can be as low as 14 feet, sometimes higher. Tenancy is varied, but includes a variety of technology companies. For many businesses, especially startups and small to medium enterprises, flex buildings provide an affordable way to have both office and production or storage space without leasing two separate facilities. Buildings are typically on the smaller side and can be relatively easily reconfigured to suit new tenant needs. Flex buildings are often found in commercial areas, but they are usually located closer to urban centers than bulk distribution properties, which is beneficial for businesses that want proximity to both clients and production facilities. In practice, there may be some overlap with light industrial and flex buildings.

Source: NAI

Manufacturing

According to NAIOP, the Commercial Real Estate Development Association, a facility designated for manufacturing is typically less than 20 percent office space and has loading docks for trucks and clear heights of at least 10 feet. There are two types of manufacturing buildings: heavy manufacturing and light assembly. Heavy manufacturing properties tend to be large, often with tens or even hundreds of thousands of usable square feet. They usually contain heavy-duty (and often customized) equipment, three-phase electricity and significant loading dock space. Heavy manufacturing buildings usually require a complete top-to-bottom renovation when there’s a change in tenants because of the permanent fixtures often needed to perform heavy manufacturing. Light assembly properties, on the other hand, are smaller, simpler and easier to move into because the interior of the building tends to be easy to reconfigure. Equipment in this type of industrial building is typically lighter and more portable because the parts being assembled are smaller than those made in a heavy manufacturing facility.

Source: Prologis

Industrial Outdoor Storage (IOS)

Industrial Outdoor storage (IOS) is a unique property type as there are essentially no buildings. Properties are appropriately zoned, large open storage areas for many items that do not need the protection of a building from weather or other concerns. Because there is no building, lease rates are considerably lower than comparable warehouse space making them popular options when suitable. As vacant, proximate land is at a premium, thus outdoor storage is a growing institutional property subtype as it commands rental rate increases and may also serve as an interim use for redevelopment. Rent growth potential is a factor of the savings from not requiring the use of warehouse buildings.